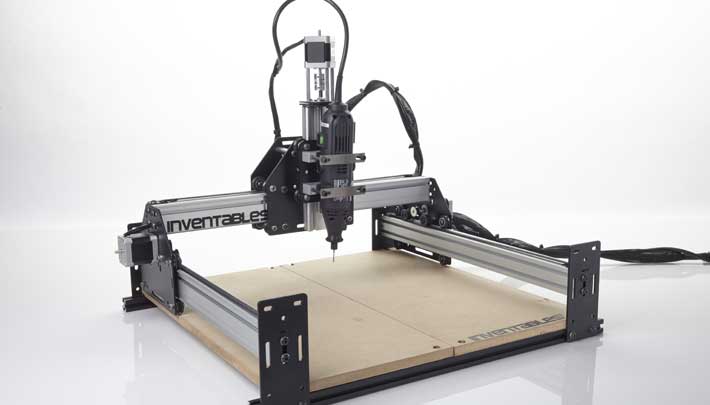

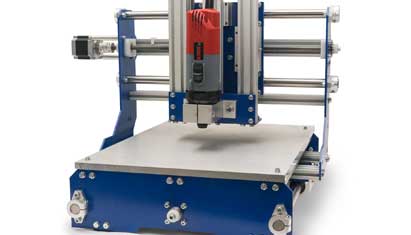

A desktop CNC machine is a compact cutting tool with CNC capabilities that can process a variety of materials. There are several parameters to consider when purchasing a machine. The footprint of a desktop machine will influence the size of the workpiece. Other important parameters include material versatility, speed, and programmability. Most machines come with a PRO version. This version has more advanced features. A basic desktop CNC machine is capable of cutting aluminum, wood, and plastic.

Lightweight Desktop CNC Machines

This type of desktop CNC machine isn’t built to do heavy-duty work. Because of their size and low power, they’re generally not meant for metal plates. However, their versatility makes them suitable for cutting soft-metals like plastic. The maximum build size of a desktop CNC is less than an inch. If you’re considering purchasing a desktop CNC for your home, it’s important to choose the right model.

Easy to Use

A desktop cnc mill is an excellent option if you want to produce small-scale designs on a budget. These models have high precision capabilities and can be easily customized with different attachments. Most machines come with a workbench and are easy to use. Learning G-code is not a big deal for a beginner. In fact, you’ll likely find that your machine’s functionality exceeds your expectations.

Can Handle a Variety of Materials

While desktop CNC machines are not built for heavy-duty work, they’re more flexible and can handle a variety of materials. You can mill plastics, wood, and even soft metals. Harder materials should be left to larger, more expensive tools, such as a full-sized CNC machine. With a little planning, you can get a desktop CNC that suits your needs. Its versatility and ease of use make it a great choice for a hobbyist or someone who wants to learn more about CNC.

Uses Various Projects

A desktop CNC machine can be used for a wide variety of projects. Unlike a standard CNC, it doesn’t have the same capacity and is not a replacement for a standard CNC. These machines are much more expensive than desktop CNC machines. They should be purchased only if you’re ready to learn how to use them effectively. You can also use a desktop machine to create a CNC in-home project.

Choosing a Desktop CNC

Choosing a desktop CNC is an excellent way to get started in the world of CNC technology. Depending on your needs, it can cut aluminum, plastic, and hardwood. The best desktop CNC will also have a control system and an enclosure for safety. If you need to be more flexible, you can build your own. This way, you can be more creative and experiment with different materials. When buying a CNC machine, you can be sure that the machine you’ll buy will work for your needs.

Automates Almost Any Process

CNC machines are useful for many purposes. They can automate almost any process. All you need is time, resources, and imagination. You can feed raw materials into the machine, and the machine will turn out the parts you need. Then, you can package and sell them for a profit. It’s easy to get started with a CNC desktop, and it’s also a great investment for hobbyists and small businesses.

Conclusion:

Desktop CNC machines are smaller versions of industrial CNC machines. They can fit on a standard work desk. They’re perfect for DIY enthusiasts and small businesses. Common desktop models include laser cutters, mills, and lathes. A benchtop CNC machine is even smaller than a desktop one. They can be used to make simple objects and even more complex ones. But there are some advantages to desktop CNCs.